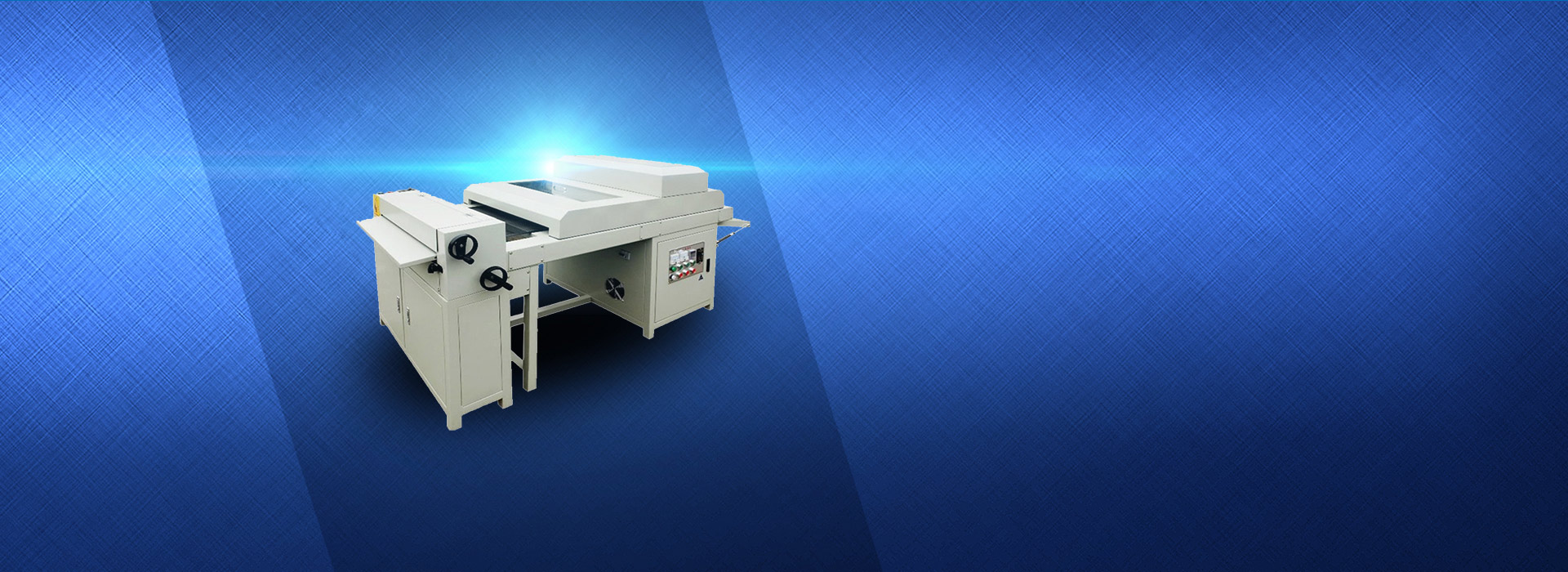

automatic edge banding technology and applications

Automatic edge banding technology has developed at a relatively high level. For example, German Homag Company first launched laser edge banding technology in 2010, thus completely solving the problems of unsightly edge banding and environmental protection. Domestic enterprises still have a long way to go in this cutting-edge technology field. Moreover, at present, only straight line automatic edge banding machines are produced in China, and there is no design in the field of curved edge banding, because this process is relatively complicated and the development cost is relatively high, and it is still mainly in the hands of foreign manufacturers.

The automatic edge banding machine is an important process in the panel furniture manufacturing process. The quality of the edge banding directly affects the quality of the product. And the corners are damaged during use, and the veneer layer is lifted or peeled off. At the same time, it can play the role of waterproofing, sealing the release of harmful gases and reducing deformation. It can also beautify the furniture and make you happy. Automatic edge banding machine panel furniture production The raw materials used by the enterprise mainly include particle board, medium-thick board and other wood-based panels. The edge banding strips mainly include PVC, polyester, melamine and wooden strips. Different edge banding equipments are used for different materials and specifications. Automatic sealing The edge banding machine is a commonly used edge banding machine for manufacturers at present. This machine mainly includes two types: manual straight curve edge banding machine and automatic straight line edge banding machine. It has a simple structure and is easy to install. However, due to its complex structure, high manufacturing precision, high price, and convenient use and maintenance, the automatic linear edge banding machine is prone to problems of one kind or another during use. Therefore, it is necessary to install and debug a fully automatic linear edge banding machine , It is an important guarantee to maintain its long-term stable working state and complete high-quality edge banding operations.

中文

中文 English

English